Our research

Construction circular economy

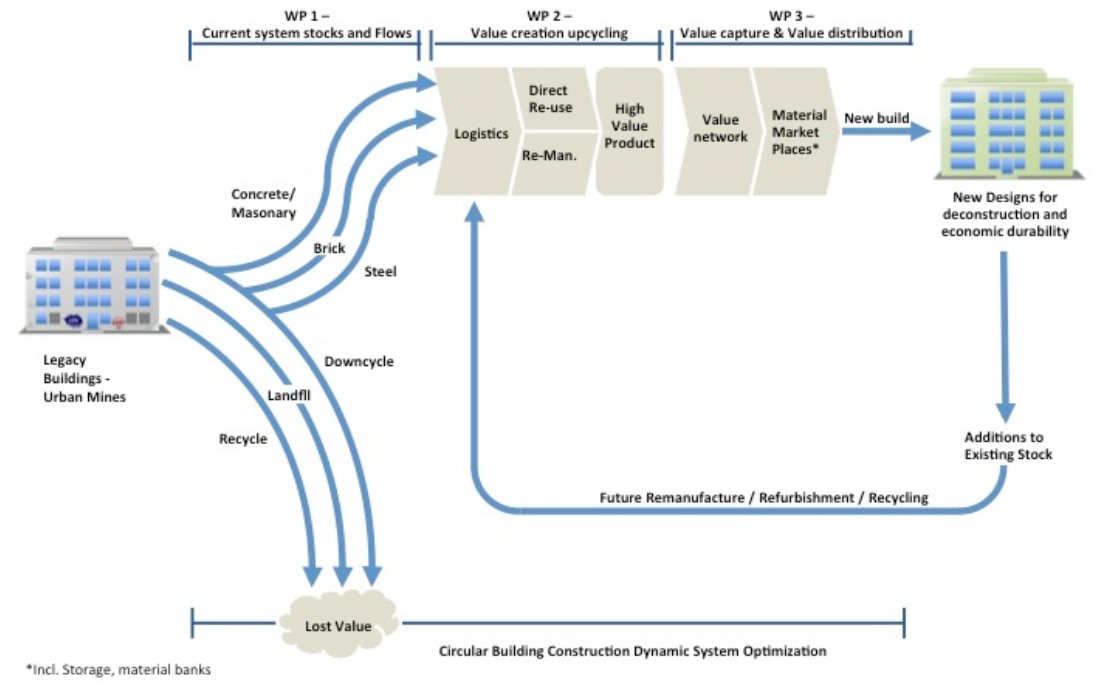

The construction industry has traditionally followed a wasteful linear model, in which fresh materials are extracted, made into products and systems such as buildings, which are then demolished at the end of their service life to become construction waste. In a circular economy, growth comes from ‘within’, by increasing the value derived from existing economic structures, products and materials.

Increased value in a circular economy derives from maintaining the integrity of a product at a higher level (technical and economic durability), using products longer (repeat use), cascading use in adjacent value chains and creating pure, high-quality feedstock (avoiding contamination and toxicity). Construction and buildings have the highest potential for circular economy innovation, value retention and creation opportunities.

With support from two substantial EPSRC grants, we are carrying out pioneering research to investigate new methods of design and construction of steel-framed structures (which are the most common type of structure for multi-storey construction in the UK) that can be easily demounted for future new build (EP/N011201/1), and methods of reclaim, repair and remanufacture of structural components from existing brick, steel and concrete buildings (EP/P008917/1).

Fire safety and high temperature performance

Our group has established an international reputation for original research and industrial impact on structural fire engineering. We have made significant contributions to understanding the complex behaviour of structures exposed to fire and developed widely adopted industrial standards and guidance.

Of particular note is our research on interactions in whole structures in fire, tensile membrane action in composite floor slabs, and fire resistance of concrete-filled tubular columns.

Our design guides form part of the UK and European structural fire engineering standards and have been used in numerous real-life projects. We have also carried out pioneering research to characterise temperature-dependent thermal and combustion properties of materials, including intumescent coatings, graphene composites and porous materials.

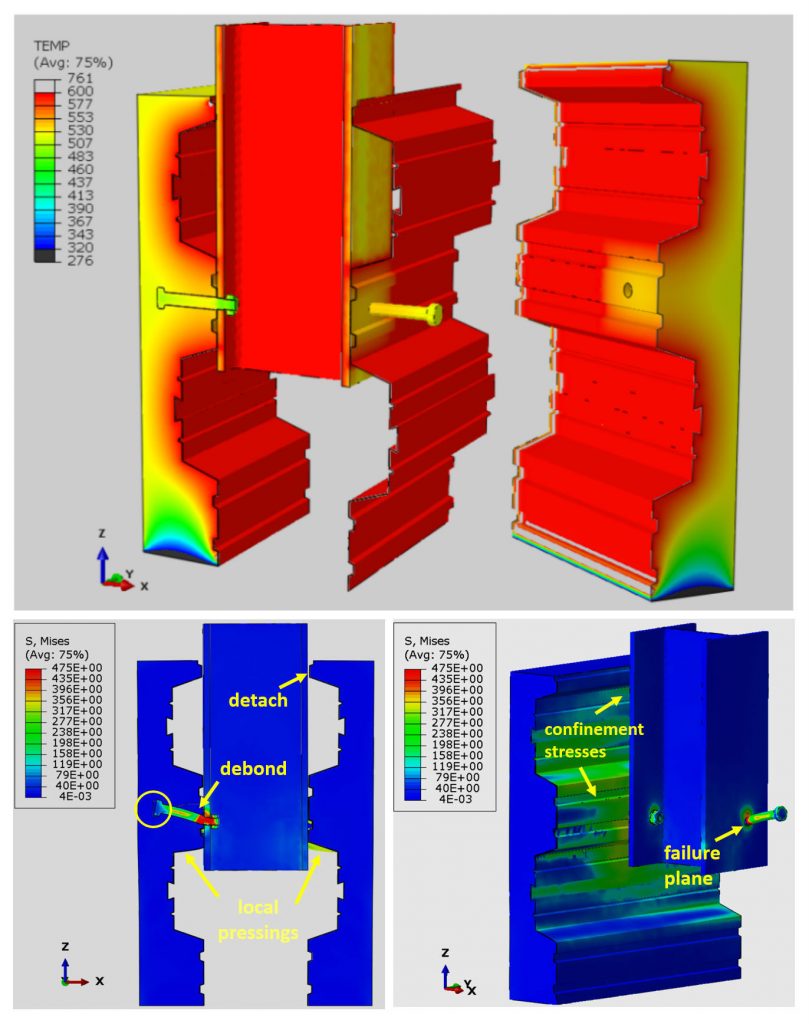

Our research combines carefully planned and executed high temperature and furnace fire tests on materials and structural systems with advanced numerical modelling.

Our new experimental facilities include full-scale Multi-Dimensional High Temperature Facility (MDHTF) to allow us to obtain three-dimensional constitutive relationships of materials at temperatures up to 1,000oC, and high strain rate, high velocity and high temperature test facility (H3TF), capable of testing full-scale material specimens under combined impact and high temperature.

These two facilities form part of the UKCRIC National Centre for Infrastructure Materials, in collaboration with Imperial College and University of Leeds.

Push-out test of demountable shear connectors for a new composite flooring system at ambient and elevated temperatures

Impact, explosion, shock and transportation safety

Our research on performance of materials and structures under impact, explosion and mechanical shock is internationally recognised. We conduct fundamental research on materials and structures under impact and explosion, including:

- penetration mechanics

- mechanics of cellular solids

- dynamic behaviour of engineering materials at high strain-rates

- structural response to impact, blast and shock loads,

- structural crashworthiness

- protective technology

- multi-scale mechanics and modelling.

We have made significant contributions to methods of determining dynamic strength of brittle materials, characterisation of the dynamic behaviour of cellular solids, and the effects of shock environments on equipment and components.

Our research results on concrete penetration have been adopted by a major safety assessment procedure for impact loads (R3-Impact Assessment Procedure, developed by the UK nuclear industry).

We collaborate with industry to develop structural design and damage/injury criteria, eg. material models of interior polymer (JLR), optimal design of the high-speed train crush zone, helmet safety and multiscale modeling of Li-ion batteries under mechanical abuse.

We are involved in developing the latest generation of crash test dummies, enhancing vehicle occupant and pedestrian safety (in collaboration Cellbond). Crash test dummies are a complex assemblage of structural materials, transducers and a protective skin.

The new crash test dummies are designed to correlate closely with the dimensions and characteristics of the human body. Thus they can simulate the movements of a real human during impact crash testing.

Researchers preparing shock tests on one of our high-speed gas guns to investigate shock response and damage of electronical and mechanical components

Long-term performance

The need to ensure longevity of the built environment is a key step towards sustainable communities. The increased frequency and intensity of extreme environmental events puts additional demand on existing structures and presents a major challenge to future resilience.

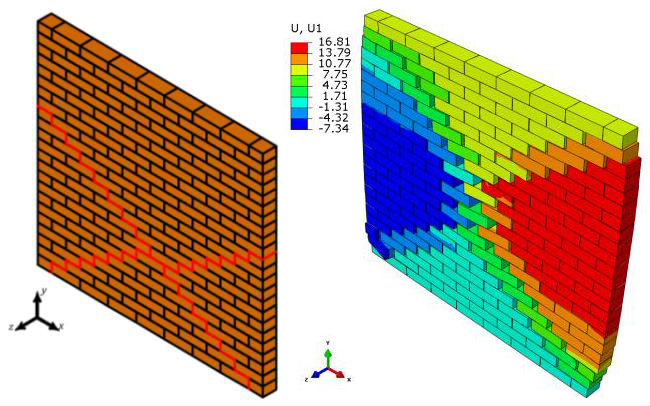

We conduct award-winning research on strengthening existing structures and improving resilience of construction forms be it steel, concrete masonry or timber. Our research uses high-technology materials such as advanced composites and leading numerical and experimental methods to help improve resilience of vernacular low-technology construction common in the developing world. We have particular expertise in the response of structures to flooding, storm and tsunami wave inundation and associated strengthening.

Key to developing optimum structural performance is the long-term behaviour of the chosen structural material. We are expert in the environmental degradation of construction materials. This extends to the response of common materials to the marine environment where chemical, biological and mechanical degradation processes are highly elevated.

In the case of chemical degradation, research on the use of combined impressed current and carbon fibre structural strengthening (ICCP-SS) has led to potential service life increases of up to 40 years for reinforced concrete elements in high chloride environments.

Masonry wall under in-plane cyclic load: experimental crack pattern (left), corresponding numerical crack pattern (right)

Facilities

Our researchers in Structural Resilience enjoy access to world-leading impact and explosion facilities.

Opportunities

Find out about research opportunities in Structural Resilience and how to apply.

Activities and events

Find out about upcoming seminars, conferences and courses.